More Trenchless Thoughts - Part III

The wondrous thing about trenchless technology, engineering, and geology, is that as geology defines the constraints on a particular process, engineers and innovators solve the problem with creative methods, and come up with entirely new methods of doing the work. The trenchless community, though there is competition between manufacturers, vendors, and contractors, will work together frequently to spread the word that there IS a better way of utility installation and renewal out there, one which doesn't involve the risks or expense of a trench.

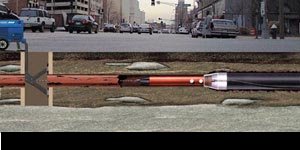

One recent example I've become aware of is pipe bursting. A pipe bursting "head" or bursting tool is used to split apart pipe and enlarge the hole around the pipe while new pipe is pulled into place. This can be accomplished with what's called "static" pipe bursting (actually the whole process is QUITE dynamic and exciting) or by pneumatic pipe bursting. In either case, new utility pipe which is larger than the original is pulled into place by a winch or pulled behind a pneumatic attachment which bursts the original pipe. The method works quite well for clay sewer pipe and concrete, as well as plastic pipes. With the addition of a cutting or scoring tool, you can even do it with iron or steel sewer or water pipe. The example below illustrates how pipe bursting is done. This is from TT Technologies' website at http://www.tttechnologies.com . They are a leading manufacturer of static and pneumatic pipe bursting equipment, as well as manufacturers of horizontal directional drills and pipe ramming equipment.

Geology, or the rock and soil conditions around the sewer pipe, is a very important consideration. When you burst a pipe, the fragments of the old pipe are pushed into the surrounding soil. Bursting works quite well in clayey soils, but it isn't done in conditions that originally had to trench into underlying rock. The rock provides a confining pressure to the soil around the pipe, and forces which would normally disperse into the surrounding soil along with the pipe fragments are directed upwards. This causes humping of the soil above. It can cause 'speed bumps' in highways. It can cause foundations to crack, and small building walls to crack or move. This is not a good thing, when damage is created when you're trying to upgrade a pipe.

Several options ARE available to you if you still want to install the pipe, that DON'T include open cutting the road. One is to use a small horizontal directional drill between manholes, with a "pipe reaming" attachment (this is a PATENTED process, developed by John Nowak of Kansas, and is called 'InneReam'), which actually removes the old pipe while you're drilling. Pipe bursting is STILL a good method for upgrading pipe between manholes. It may have some limitations, but you can get the job done in one way or another, and still do it with trenchless methods.

As always, the mention of TT Technologies and John Nowak's InneReam method does not imply approval nor endorsement by Trenchless Geologist. This information is provided to the reader to make his or her own decisions, and to encourage the use of trenchless technology.

Until next time,

Trenchless Geologist

0 Comments:

Post a Comment

<< Home